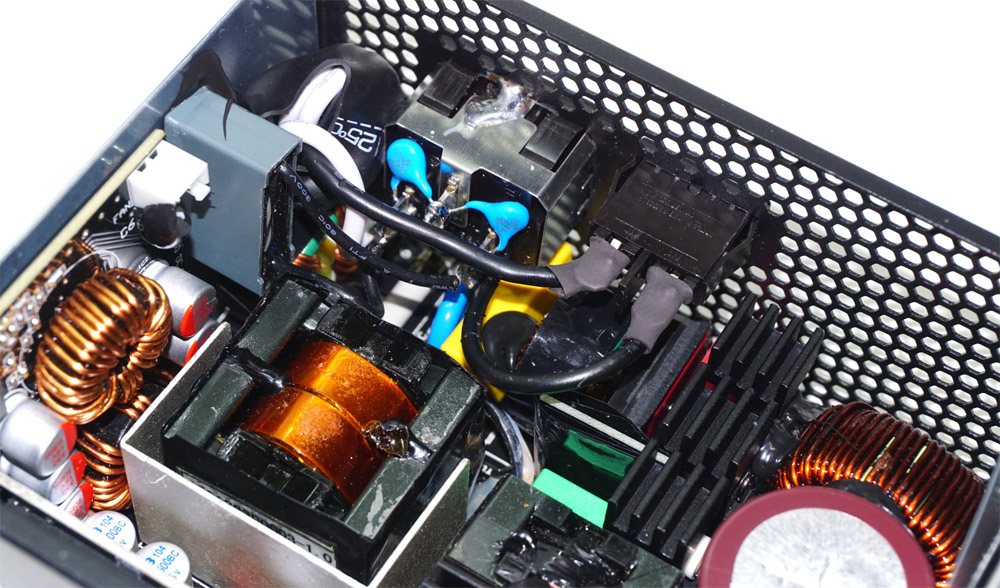

Switching power supplies form the foundation of every electronic system. In this article, we will introduce the top 5 causes of switching power supply failures. Choosing a high-quality and reliable switching power supply is the basis for ensuring the stable operation of any electrical system. Our aim in writing this article is to provide you with the precautions you need to take to avoid this type of system failure when doing your design work.

Top Causes of Switching Power Supply Failures

The stable working of a switching power supply depends on certain temperature conditions. A fundamental principle of physics states that for each 10°C reduction in the switching power supply’s environment below 40°C, you effectively double the mean time between failures (MTBF). Conversely, for every 10°C rise in the switching power supply’s ambient temperature, your MTBF is halved, resulting in reduced reliability. It’s worth noting that many, though not all, of the failure factors outlined in this list are temperature-related.

Increasingly, we are observing a shift towards the utilization of plastic chassis for end-equipment, as opposed to the traditional metal chassis that have been in use for a considerable duration. This transition significantly influences thermal performance and electromagnetic compatibility (EMC). Therefore, any measures taken to improve thermal management around your switching power supply within the system are of paramount importance.

1. Fans

Fans represent the primary cause of switching power supply failures. Being the sole electromechanical component within switching power supplies, fans are susceptible to failure, even in well-designed units. It’s not uncommon to encounter situations where switching power supplies are initially specified without fans, only to have end-users later add fans to dissipate heat from the entire system. However, this approach essentially shifts the issue from one location to another.

Eliminating the fan enhances reliability by a significant 25%, offering the optimal solution for averting failures. A well-crafted design that maintains the switching power supply’s efficiency at a sufficient level renders fans unnecessary.

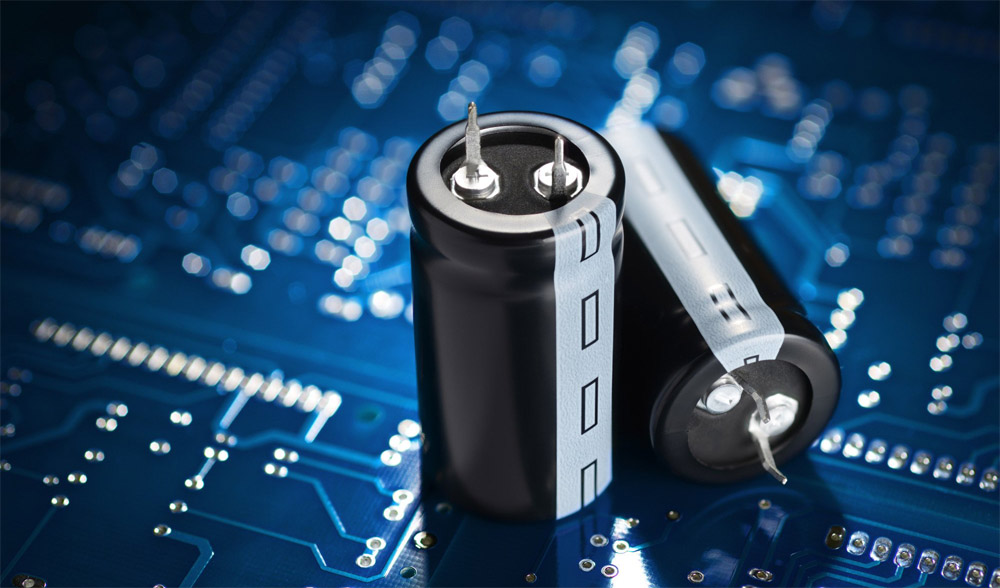

2. Capacitors

Contrary to common belief, significant advancements are continually being achieved in capacitor technologies each year. Nonetheless, capacitors are susceptible to failure when subjected to excessive stress or when substitutions are introduced during production or through counterfeiting.

Capacitors, particularly electrolytic ones, can exhibit various failure modes, such as swelling, leakage, explosion, short-circuiting, reduced capacitance, or elevated in-circuit Equivalent Series Resistance (ESR). On occasion, excessive heat can lead to capacitor damage. In the case of electrolytic capacitors, chemical leakage may occur, potentially resulting in additional harm, including corrosion that affects PCB traces and other associated issues.

To prevent potential failures, it is advisable to opt for high-quality capacitors from reputable brands. Additionally, it’s essential to maintain capacitors at lower temperatures whenever possible and monitor ripple currents to ensure they are not subjected to excessive stress. It’s worth noting that the storage life of electrolytic capacitors is limited to two years without power applied to the switching power supply, a detail that often goes unnoticed. As power designers, we make every effort to minimize the use of electrolytic capacitors, but when their use is unavoidable, we prioritize sourcing the highest-quality options available.

3. Power Components

Power switching components, specifically MOSFETs, bear the primary operational load of the switching power supply and can, at times, lead to failures when heat dissipation is insufficient. Additionally, overstressing of drain overvoltage, drain overcurrent, gate overvoltage, or the internal antiparallel diode can contribute to these failures.

Effective design practices and component derating significantly contribute to prolonging the operational lifespan of MOSFETs within the application. By prioritizing proper design, addressing control circuitry, conducting loop testing, and implementing derating strategies, you can ensure both the reliable operation and extended longevity of these components.

Power diodes may experience failures when there is inadequate heat dissipation, insufficient thermal management, or insufficient airflow. Schottky diodes, in particular, can be susceptible to damage from overvoltage when driving inductive circuits, and they are less forgiving in this regard compared to MOSFETs. Additionally, switching losses in rectifiers can generate substantial heat. Temperature-related issues, such as TRR tails due to extended switching times, can lead to increased heat, potentially resulting in a positive feedback loop and component damage. To mitigate these concerns, it is crucial to carefully consider them during the design phase and take measures to minimize dissipation through proper design, component selection, characterization, and derating.

4. Control ICs

Control ICs can exhibit unconventional operating characteristics that, when not properly understood or applied, can result in failures. Issues like incorrect clock operation or inadequate PCB layout can render control ICs vulnerable to noise or oscillations. It’s essential to thoroughly grasp the behavior of each controller IC used in the application, including any workarounds and “undocumented features” specific to the intended use case. This knowledge is vital for ensuring the correct and reliable operation of control ICs.

To prevent failures when using commercial control ICs, it’s crucial to have a comprehensive understanding of startup conditions. This includes implementing current limiting, employing soft-start modes, ensuring proper gate drive, maintaining appropriate spacing, and carefully monitoring the control loops. These measures are essential for achieving stable operation across all conditions. The reliability of control ICs is paramount, as any failures or instability in their operation can result in significant damage to the MOSFETs, which bear the brunt of the energy during such occurrences. With the increasing utilization of digital controllers in power electronics designs, issues may arise related to software and control ICs, and sometimes, it’s the control IC itself that fails. However, in most cases, it’s the switching MOSFETs that ultimately suffer the consequences.

5. Environmental Causes

Moisture ingress stemming from the use of disinfecting solutions in medical electronics can pose environmental challenges, especially when these liquids enter the switching power supply through ventilation openings and fan ports. This concern underscores the importance of considering fan elimination to mitigate such risks. Moisture can corrode electronic components over time, ultimately leading to equipment failures. Additionally, environmental factors, such as surges and transients exceeding the ratings outlined in various IEC standards, can result in damage to semiconductor components located in the switching power supply’s front end. While some of these environmental issues can be addressed through application-specific design choices, others may remain beyond control.

Environmental challenges such as lightning strikes and induced power-line surges and transients pose potential threats. However, their impact can be mitigated through meticulous switching power supply design and testing, as well as the integration of external protection components. Surge-protection devices, known for their capability to withstand significant transients and surges, can safeguard the AC input of a system effectively. In recent developments, newer switching power supplies are equipped with built-in surge protection mechanisms, with some designed to withstand line surges for up to five seconds, recognizing the variability in power-line stability on a global scale.

Conclusion

Switching power supplies have many advantages over traditional linear power supplies. However, various conditions can lead to switching power supply failures. The above-mentioned ones are the most commonly observed based on research. When embarking on system design, it’s crucial to prioritize the switching power supply as a primary consideration rather than relegating it to a secondary role.

For a manufacturer of switching power supplies that pursue product quality and long-term stability of customers’ applications, they should choose to use legitimate components to create a well-designed and robust system. This is exactly what Power1986 has been doing. In product design, problems from the customers and their long-term experience are constantly incorporated into the design of new products. By doing so, it increases the reliability of the switching power supply system and reduces the failures that customers may encounter.

If you are about to purchase switching power supplies, please browse our Switching Power Supplies or Contact Us directly.